Gray Iron Foundry Sand Casting Front Suspension Connection Bracket

Dandong City Pengxin Machinery specializes in production Gray Iron Sand Casting Front Suspension Connection Bracket

- China

- Gray Cast Iron

Product Detail

Product descriptions from the supplier

What We Do

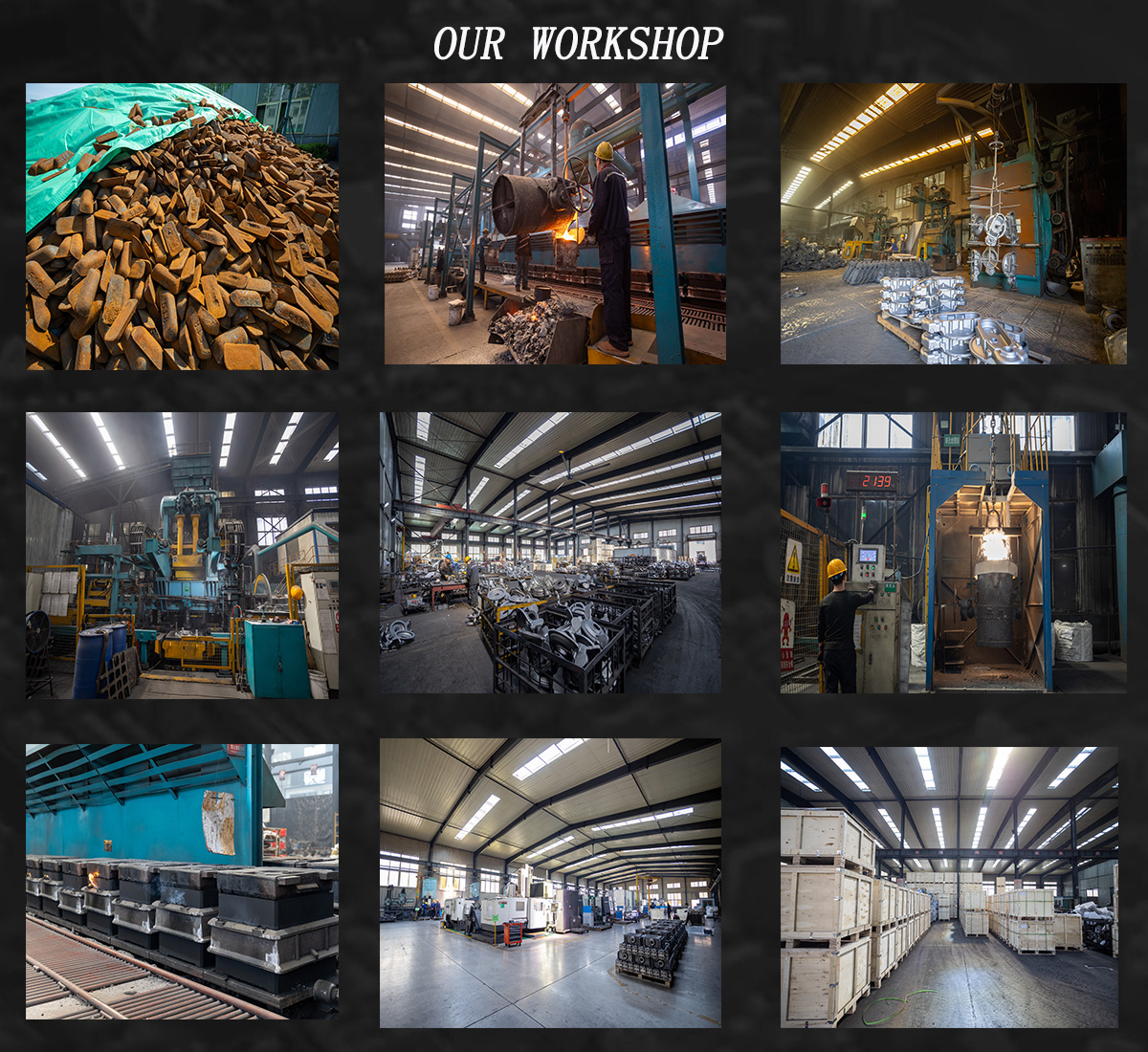

Dandong Pengxin Machinery Co., Ltd., founded in 1958, is a private enterprise specializing in casting, machining, and assembly. Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons.

Equipped with advanced technologies like high-pressure molding and Japanese FBO Ⅲ production lines, it produces up to 30,000 tons/year. Facilities include 12-pulse electronic furnaces, CNC machines, and a quality inspection center with precision instruments.

Sell to 80+ countries and regions worldwide, serving large companies such as John Deere, Mercedes-Benz, John Deere, and Weir, Pengxin welcomes partnerships, prioritizing quality, service, and customer satisfaction.

Service

Pre-Sales

Get your purchasing needs → Confirm order drawing→ Give customized solution → Offer a quotation → Make the pattern→ Provide samples→ Bulk production after samples approve the test.

On Sale

Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control.

After-Sales

Proactively get your feedback→ Engineering team gets involved→Casting engineer conducts metallographic and spectral tests based on the inventory test rods→Machining engineer's CMM inspection is based on the inventory samples→Provide solutions based on the test results→Welcome to contact us for your customized solution.

30,000 tons+Annual production capacity for Aluminum.

80,000 tons+Annual production capacity for Steel.

4000+Mold develop production.

Quality Control

Pattern Control

We simulate feeding syetem to check the pattern desgin from the filling process and material solidification,In this way, we can shorten the mold development cycle, reduce the number of mold trials and improve product quality.The software we use includes Abaqus,Moldflow and Moldex3D,simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

We check the chemistry property as new raw material coming.

Raw Casting & Machining Control

All dimensions 100% measuring

Raw material spectral analysis and X-ray detection Critical dimensions with CMM measuring.

Our Process Control

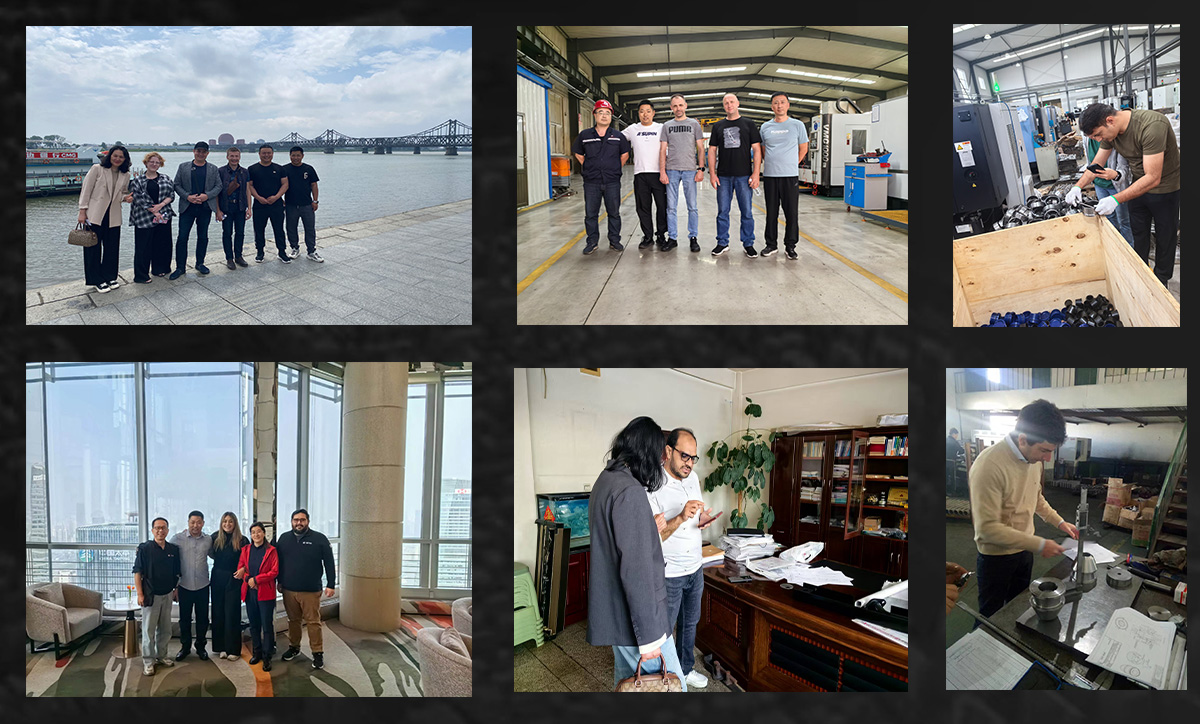

Our Team