SERVICE

Get your purchasing needs → Confirm order drawing→ Give customized solution → Offer a quotation → Make the pattern→ Provide samples→ Bulk production after samples approve the test

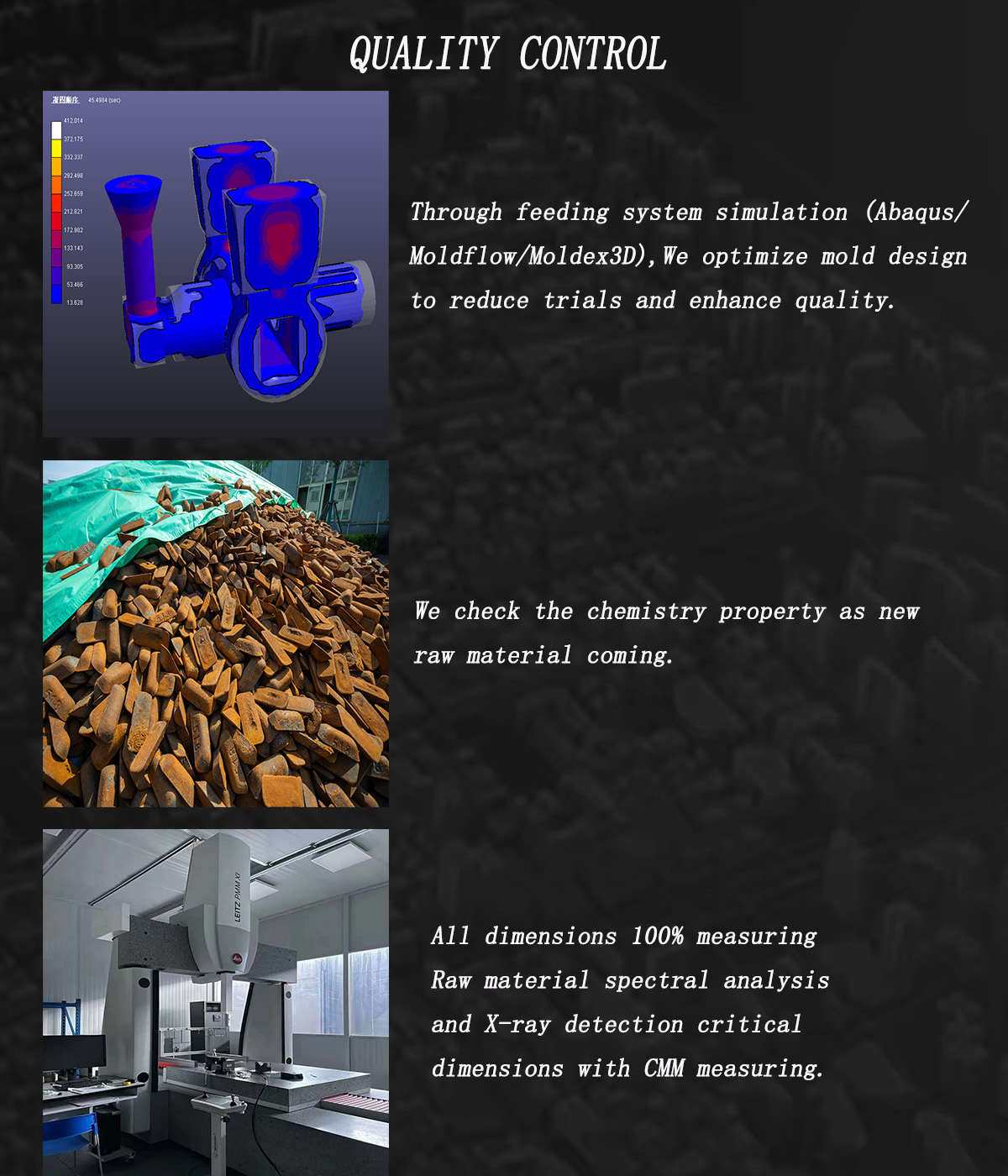

At Pengxin-Casting, process control begins as early as in the planning and development phase of the products. We support our customers to perform all required tests and inspections in a laboratory. It goes without saying that our plants are certified according to ISO 9001 and IATF16949 in line with a validated quality management. As we strive to accomplish our zero-error policy, you can rely on the following process control measures: Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control.

Equipped with advanced technologies like high-pressure molding and Japanese FBO Ⅲ production lines, it produces up to 30,000 tons/year. Facilities include 12-pulse electronic furnaces, CNC machines, and a quality inspection center with precision instruments.

Sell to 80+ countries and regions worldwide, serving large companies such as John Deere, Mercedes-Benz, John Deere, and Weir, Pengxin welcomes partnerships, prioritizing quality, service, and customer satisfaction.

Our Team

What Our Happy Clients Say?