Why Gray Cast Iron Remains the Gold Standard for Machine Bases

2025-10-10

In an era of advanced composites and high-tech alloys, gray cast iron continues to be the unsurpassed choice for machine bases and support structures. Its enduring dominance is not a matter of tradition, but a testament to its unique and irreplaceable combination of properties that directly meet the demands of precision engineering.

The cornerstone of gray cast iron's superiority is its exceptional damping capacity. The flake graphite microstructure inherent to the material effectively absorbs vibrational energy, preventing "chatter" from propagating through the machine tool. This is critical for achieving superior surface finishes in machining and ensuring the accuracy of sensitive measurement equipment, outperforming stiffer materials like steel which can ring and transmit vibrations.

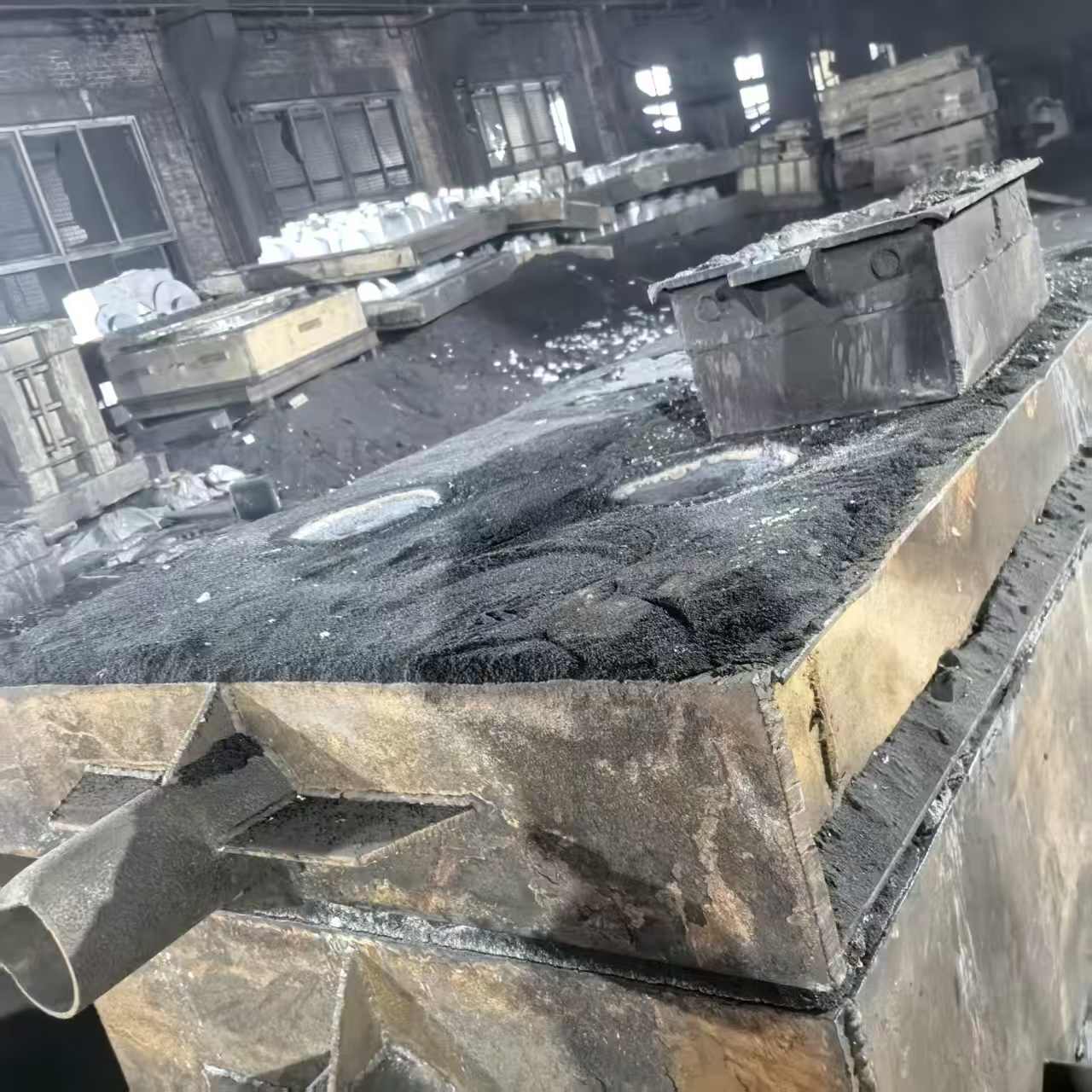

Beyond damping, gray cast iron offers excellent compressive strength, making it ideally suited to support heavy static loads without deformation. Its wear resistance ensures long-term stability of critical mounting surfaces. From a manufacturing standpoint, the castability of iron allows for the creation of complex, ribbed geometries that optimize stiffness and reduce weight in a single, stress-relieved component.

Finally, gray cast iron presents an unbeatable cost-to-performance ratio. While the initial material cost is low, the true value lies in its lifecycle. The reduction in vibration-related downtime, maintenance, and scrap parts delivers substantial long-term savings. For applications demanding unwavering stability, from CNC machining centers to coordinate measuring machines, gray cast iron remains the foundational material against which all others are measured.