Key Benefits of Using Cast Iron in Industrial Machinery

2025-11-23

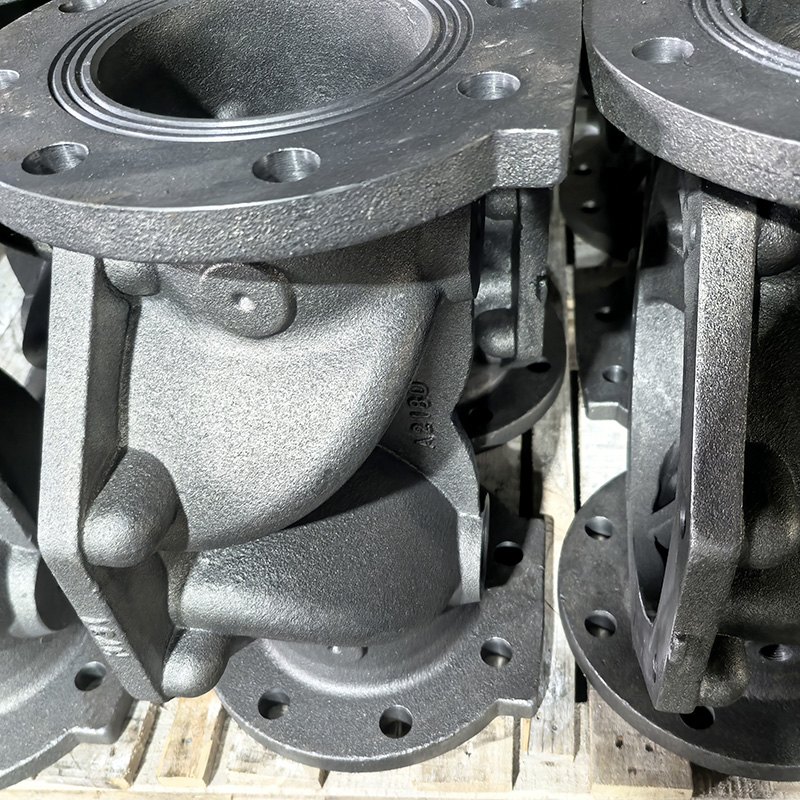

When selecting materials for industrial machinery, engineers prioritize performance, reliability, and cost-effectiveness. Among the top contenders, cast iron consistently proves its mettle. Its unique combination of properties makes it indispensable for a wide range of demanding applications. Let's delve into the key benefits of cast iron from a technical and practical perspective.

1. Superior Mechanical Properties: Strength and Damping

Cast iron excels in compressive strength, making it ideal for components like engine blocks, machine tool bases, and hydraulic press frames that must withstand significant loads without deforming. More uniquely, cast iron offers exceptional vibration damping capacity. Its graphite flakes or nodules absorb vibrational energy, reducing noise and preventing chatter in precision machining and power transmission systems. This inherent damping is superior to most steels, leading to improved surface finish and longer tool life.

2. Enhanced Performance: Wear and Thermal Resistance

The carbon content in cast iron creates a hard, wear-resistant surface. This is crucial for parts like cylinder liners, pistons, and brake discs, where friction is a constant challenge. Furthermore, certain types of cast iron, like gray iron, exhibit excellent thermal conductivity and stability. They effectively distribute and dissipate heat, minimizing thermal distortion in high-temperature environments, which is vital for maintaining operational accuracy.

3. Versatile Material and Application Range

"Cast iron" is not a single material but a family of alloys, each with tailored properties:

-

Gray Iron: Known for its machinability and damping, used for housings and enclosures.

-

Ductile Iron: Offers high tensile strength, toughness, and impact resistance, suitable for crankshafts and gears.

-

White Iron: Extremely hard and abrasion-resistant, perfect for mill liners and pump components.

This versatility allows for precise material selection for applications from heavy-duty mining equipment to food processing machinery.

4. Unmatched Cost-Effectiveness

The primary advantage of cast iron is its excellent castability. It melts at a relatively low temperature and flows easily into complex molds, allowing for the production of intricate, near-net-shape parts in a single step. This dramatically reduces machining time, scrap material, and overall manufacturing costs compared to fabricating components from steel plate or billet. The long service life and reduced maintenance needs of cast iron parts further enhance their lifetime value.

In conclusion, cast iron remains a cornerstone material in industrial engineering. Its synergistic blend of mechanical strength, damping capacity, wear resistance, and manufacturing economy ensures that it will continue to be the material of choice for robust, reliable, and cost-effective machinery.